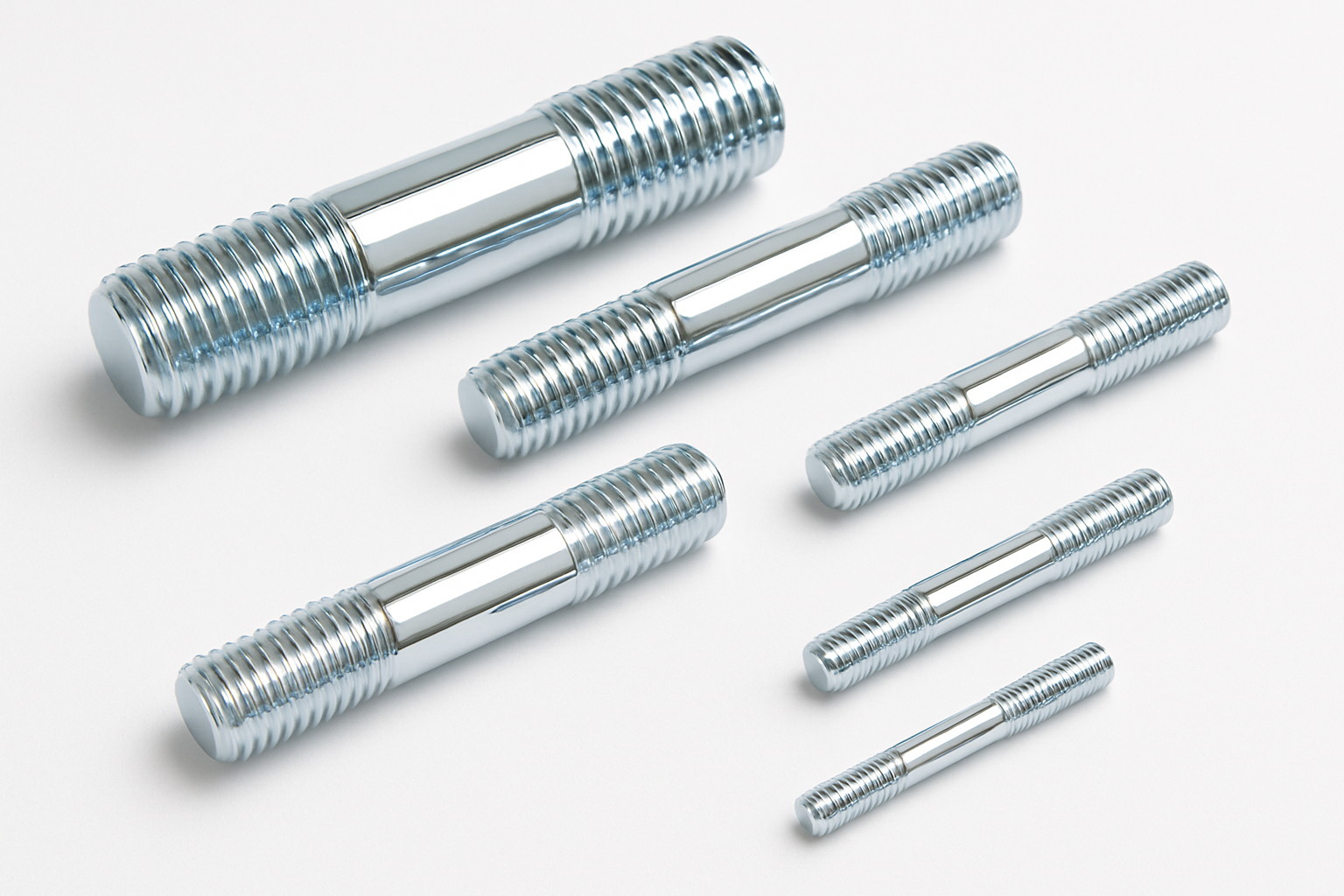

DOUBLE END THREADED STUDS MANUFACTURER

Triangle Machine Products is a precision manufacturer of double end studs designed for critical fastening applications where strength, alignment, and repeatability matter. Our double end threaded studs are fully machined to tight tolerances, ensuring consistent thread engagement and reliable performance in structural, mechanical, and high-load assemblies.

Unlike cold-headed alternatives, Triangle’s double end studs are cut and machined from bar stock, giving us full control over thread form, shoulder dimensions, and concentricity. Whether you’re sourcing standard configurations or looking for a custom double end stud, we provide components that are engineered for precision—and built to hold under pressure.

PRECISION DOUBLE END STUDS FOR RELIABLE FASTENING

Double end studs are used when components need to be clamped or fastened from both sides—allowing for assembly with two nuts, or with one threaded into a tapped hole and the other used for removable fastening. These parts play a critical role in mounting engines, structural assemblies, valve bodies, flanges, and rotating equipment where stability and serviceability are key.

Triangle machines double end studs to exact thread specifications, ensuring consistent torque behavior, clean engagement, and trouble-free installation. Whether your application involves high loads, vibration, or frequent disassembly, our studs are designed to remain secure, aligned, and dimensionally stable over time. We offer a wide range of thread lengths, chamfer styles, shoulder types, and transitional geometries to meet the unique demands of your assembly.

CUSTOM DOUBLE END THREADED STUDS TO FIT YOUR APPLICATION

Every build comes with its own set of fastening requirements—and Triangle is built to meet them. Our custom double end studs are machined to your print, whether you require equal or unequal thread lengths, custom shoulder diameters, or transition points tailored to your component interface. With CNC turning and threading capabilities, we’re able to produce complex features with speed and consistency, whether for prototype validation or long-term production supply.

We support multiple thread types including UN, metric, fine pitch, and specialty threads, and can provide studs with center points, wrench flats, undercuts, or relief grooves. Each feature is produced with the goal of enhancing performance in your specific environment—thermal cycling, torque variation, corrosive exposure, or repeated assembly. Triangle’s goal is always the same: to deliver studs that not only fit your application, but strengthen it.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS AS YOUR DOUBLE END STUD MANUFACTURER?

Triangle Machine Products brings decades of experience in tight-tolerance turning, threading, and fastener manufacturing. Our customers choose us when performance matters—when a stud isn’t just a commodity part, but a precision component in a high-value system. We machine every double end stud from high-quality materials using repeatable processes backed by real-time inspection and engineered setup.

From short runs to high-volume production, we work closely with your team to ensure manufacturability, consistent quality, and timely delivery. Whether your studs are going into power transmission systems, engine mounts, hydraulic manifolds, or aerospace structures, we produce components that match your specifications—and exceed expectations in the field.

DOUBLE END STUDS: FREQUENTLY ASKED QUESTIONS

WHAT ARE DOUBLE END THREADED STUDS AND HOW ARE THEY USED?

Double end threaded studs are fasteners with threads on both ends, commonly used for clamping, mounting, or aligning two components. One end is typically installed in a tapped hole, while the other receives a nut, allowing for removable or adjustable assembly.

CAN I GET CUSTOM DOUBLE END STUDS FROM TRIANGLE MACHINE PRODUCTS?

Yes. We specialize in custom double end studs with variable thread lengths, diameters, and features such as wrench flats, undercuts, or center points—all machined to your exact requirements.

WHAT MATERIALS AND FINISHES ARE AVAILABLE FOR DOUBLE END STUDS?

We machine double end studs from carbon steel, stainless steel (303, 304, 416), alloy steels, and other specialty materials. Finishes include black oxide, passivation, oil coating, or customer-specified treatments for corrosion resistance or torque control.

If you have any questions about our machined double end studs, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.