ROUND BELT PULLEYS: PRECISION SOLUTIONS FOR INDUSTRIAL APPLICATIONS

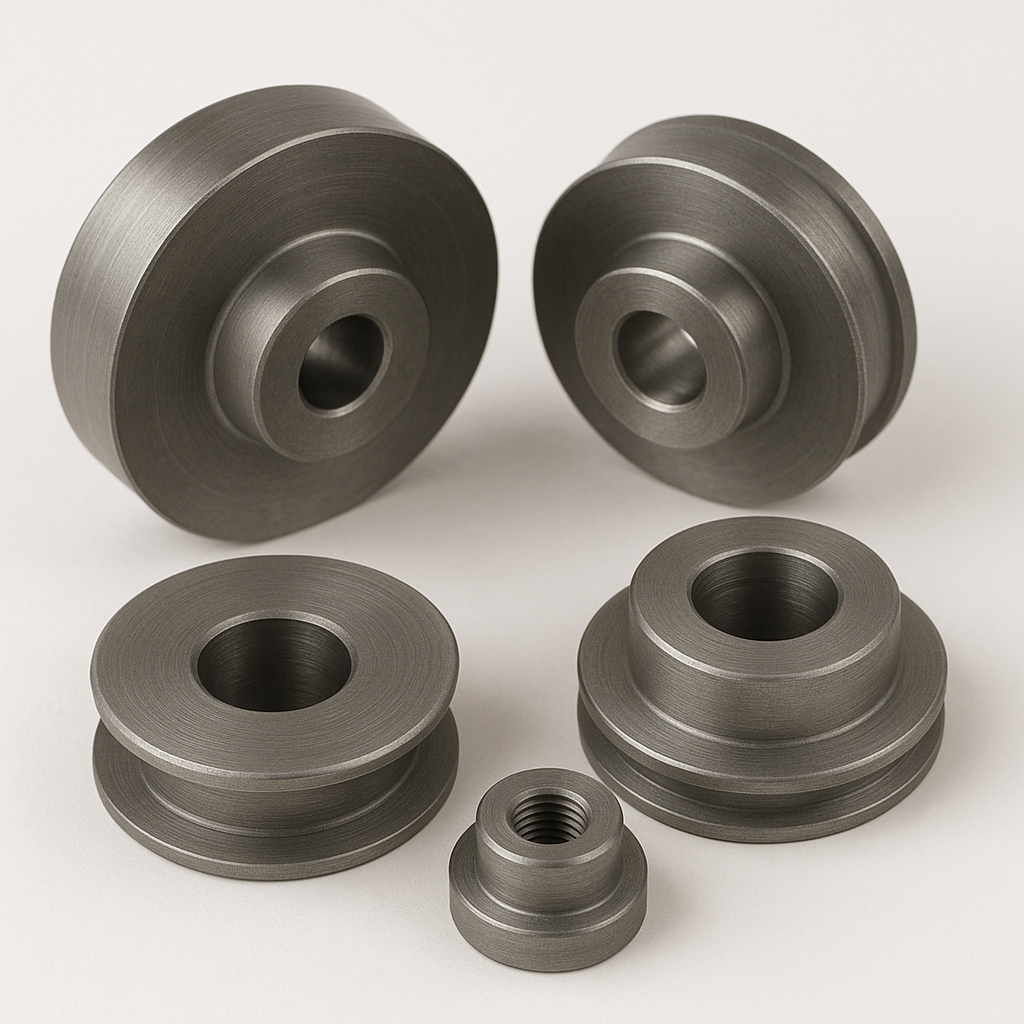

Round belt pulleys play a critical role in power transmission systems that require smooth, quiet, and low-tension operation. These pulleys are designed to guide and drive round belts—typically made of rubber or polyurethane—across mechanical assemblies that demand flexibility and reduced vibration. Triangle Machine Products manufactures precision round belt pulleys tailored for demanding industrial applications where consistent performance and exacting tolerances are essential.

As a trusted round belt pulley manufacturer, we deliver machined pulleys that offer exceptional concentricity, long service life, and compatibility with a variety of belt sizes and configurations. Whether you’re seeking replacements for legacy equipment or developing a new OEM system, Triangle’s custom pulley solutions ensure alignment, efficiency, and dependable belt tracking across your production cycle.

HIGH-QUALITY ROUND BELT DRIVE PULLEYS FOR RELIABLE PERFORMANCE

Our round belt drive pulleys are built with performance in mind—machined to tight tolerances that ensure smooth rotation and proper belt tension across a variety of load conditions. Unlike cast or molded alternatives, our CNC-machined pulleys offer enhanced surface finishes and precise geometries that reduce slippage, minimize belt wear, and maintain belt alignment even under dynamic loads.

We work closely with customers in industries such as food processing, textile production, medical equipment manufacturing, and light conveyor systems, where round belt drives are commonly used. Our pulleys are engineered for high-speed, low-noise applications and can be manufactured to fit your existing system with exact hub configurations, keyways, or bore dimensions.

CUSTOM ROUND BELT PULLEYS ENGINEERED TO YOUR SPECIFICATIONS

At Triangle Machine Products, customization is central to our manufacturing philosophy. We produce custom round belt pulleys in a wide range of diameters, groove depths, profiles, and materials to meet the specific mechanical and environmental demands of your application. Whether you need a single prototype or full production volumes, our team is equipped to deliver high-quality components on time and within tolerance.

We offer the flexibility to accommodate unique shaft geometries, clearance requirements, and specialized finishes such as hard anodizing or plating. If your round belt drive requires a specialty configuration not readily available on the market, Triangle’s engineering and machining capabilities can make it a reality—with precision and repeatability that high-volume forming processes can’t match.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS AS YOUR ROUND BELT PULLEY MANUFACTURER?

Choosing Triangle means working with a manufacturer that understands the critical performance and alignment characteristics of round belt drive systems. We combine decades of machining expertise with state-of-the-art CNC equipment to deliver pulleys that meet tight dimensional standards, improve mechanical efficiency, and reduce downtime. Our agile manufacturing approach supports short-run custom builds and long-term production contracts alike, backed by consistent quality and responsive service.

Unlike generic suppliers or cast component manufacturers, Triangle Machine Products provides precision-machined solutions built specifically for your system. We are committed to delivering functionally superior pulleys that outperform standard offerings—especially in environments where performance cannot be compromised.

ROUND BELT PULLEYS: FREQUENTLY ASKED QUESTIONS

WHAT ARE ROUND BELT PULLEYS AND WHERE ARE THEY USED?

Round belt pulleys are circular components designed to drive or guide round belts in low-tension, high-speed applications. They are often used in conveyors, light-duty motors, textile machinery, and processing equipment where smooth motion and minimal vibration are essential.

CAN TRIANGLE MACHINE PRODUCTS PROVIDE CUSTOM ROUND BELT PULLEYS?

Yes. We specialize in custom machining round belt pulleys to meet your exact specifications—whether that involves unique grooves, diameters, hub styles, or mounting configurations.

WHAT MATERIALS ARE AVAILABLE FOR PULLEYS FOR ROUND BELTS?

Triangle offers round belt pulleys in aluminum, steel, stainless steel, and specialty alloys. Finishes such as black oxide, anodizing, or chrome plating can be applied based on application needs.

If you have any questions about our round belt pulley manufacturing, or are looking for a quote, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.