INDUSTRIAL PULLEY MANUFACTURERS & CUSTOM PULLEY MACHINING

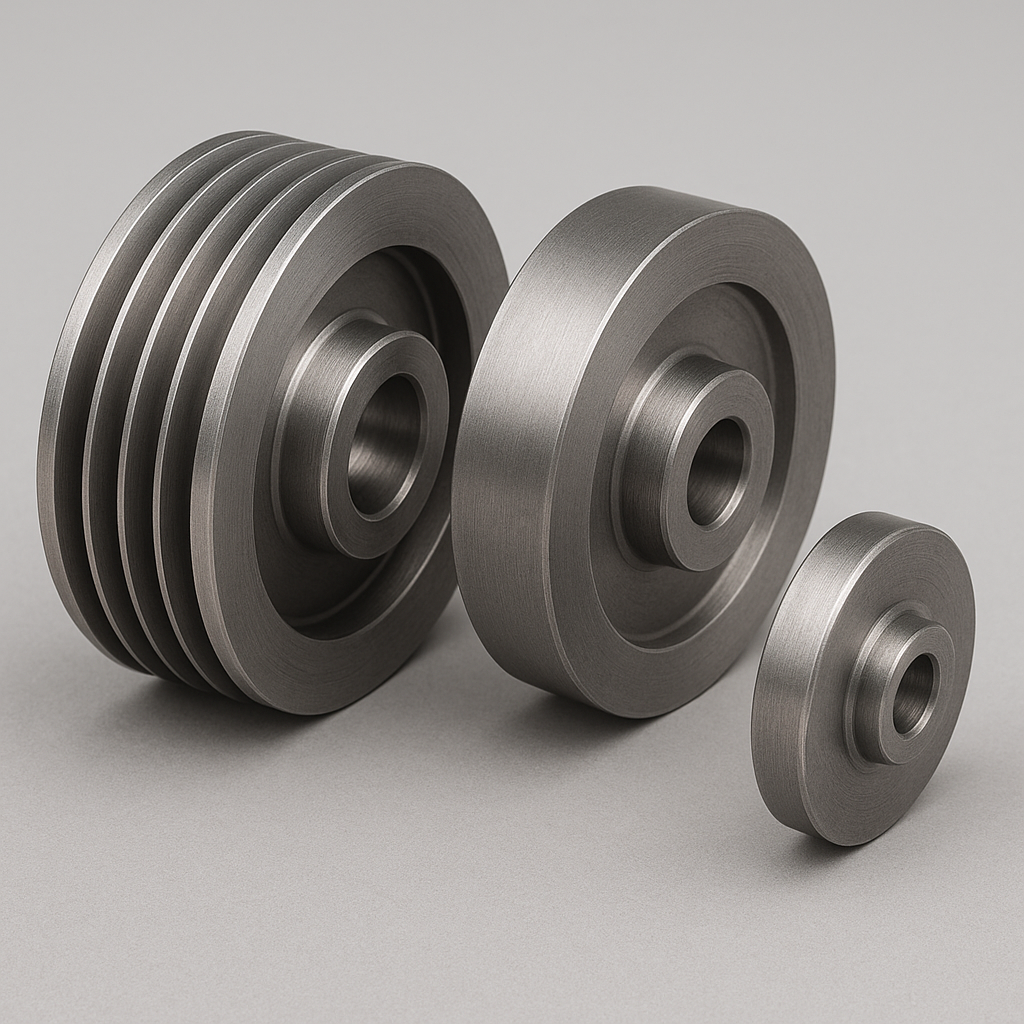

At Triangle Machine Products, we manufacture precision-machined pulleys that serve as critical components in motion and power transmission systems. As a trusted industrial pulley manufacturer, we deliver custom-machined pulleys for OEMs and equipment manufacturers who require consistent performance and tight-tolerance reliability.

Our pulleys are engineered for use in belt-driven applications across multiple industries—from factory automation to heavy machinery—where exact alignment, surface finish, and concentricity make the difference between optimal efficiency and operational failure. Whether you’re working with a V belt drive pulley or round belt pully system, our machining process ensures your pulley meets the mechanical and performance expectations of your application.

PRECISION MACHINED PULLEYS FOR INDUSTRIAL APPLICATIONS

Pulleys are more than just rotating components—they are precision tools that control speed, force, and movement in mechanical systems. Triangle Machine Products produces machined pulleys that deliver smooth belt engagement, long service life, and high-efficiency power transfer. We understand that the performance of your pulley impacts more than one part of the system—it affects overall productivity, energy use, and system longevity.

Our pulleys are used in automated conveyors, industrial blowers, pump systems, gearboxes, and power transmission setups where reliability matters. We machine each pulley to match your belt type and load conditions, including V-belt, flat belt, poly V, or round belt configurations. Whether your pulley is designed for high-RPM operation, torque-heavy applications, or precision positioning, Triangle delivers the dimensional accuracy and balance required for stable, long-term use.

CUSTOM PULLEY MACHINING SERVICES

Triangle Machine Products offers custom pulley machining tailored to your exact requirements—from geometry and material to shaft mounting features and belt groove profiles. We do not manufacture mass-market pulleys; instead, we produce application-specific parts that align with your engineering drawings, prototype development, or replacement part needs.

Our in-house capabilities include CNC turning, grooving, contouring, threading, and balancing, giving us full control over each detail of the pulley’s design. We machine custom pulley bores to fit keyed shafts, tapered hubs, or interference fits, and can create single- or multi-groove pulley systems for synchronized performance across multiple drive elements. For industries that require small-batch or repeatable production with demanding tolerances, Triangle provides flexible solutions built around quality and responsiveness.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS FOR YOUR PULLEY NEEDS

Pulleys must rotate cleanly, handle dynamic loads, and maintain reliable belt tracking over time—and the quality of the machining makes all the difference. At Triangle Machine Products, we combine deep machining experience with modern CNC equipment to ensure each pulley we produce is balanced, precise, and ready for service.

We partner with customers in automotive systems, food production, packaging, robotics, and industrial automation to deliver pulleys that meet both functional and dimensional specifications. From the first part to the final shipment, our team emphasizes clear communication, traceable quality control, and strict attention to detail. We know you can’t afford downtime due to pulley failure—and with Triangle, you won’t have to.

PULLEYS: FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF INDUSTRIAL PULLEYS DO YOU MANUFACTURE?

We manufacture a variety of industrial pulleys, including those for V-belt drives, poly V systems, round belts, and flat belts. Each pulley is machined to your specific design and belt configuration, with optional custom features such as grooves, keyways, or shaft bores.

CAN YOU PROVIDE CUSTOM PULLEY MACHINING SERVICES?

Yes. Triangle specializes in custom pulley machining based on customer prints or specifications. We can accommodate unique groove profiles, tight concentricity tolerances, and shaft mounting requirements for prototype or production quantities.

WHAT MATERIALS ARE AVAILABLE FOR YOUR MACHINED PULLEYS?

We machine pulleys from materials including aluminum, carbon steel, stainless steel, and other specialty metals based on the application’s strength, wear, and environmental demands. Material selection is tailored to optimize pulley performance and durability.

If you have any questions about our pulleys, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.