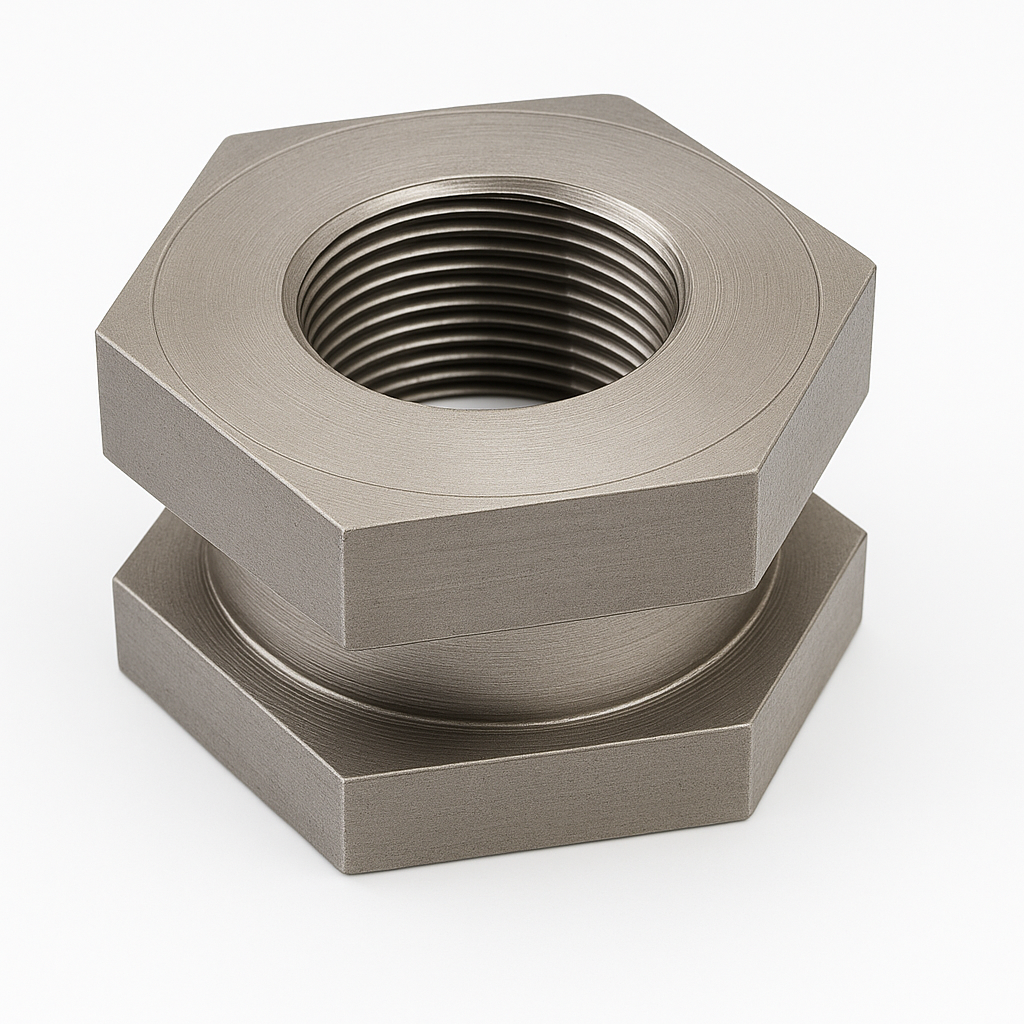

CUSTOM ADJUSTING NUTS & ADJUSTMENT NUTS MANUFACTURER

Triangle Machine Products is a trusted manufacturer of adjusting nuts, also referred to as adjustment nuts, that are engineered for precision control and long-lasting mechanical stability. Our adjusting nuts are machined to tight tolerances and are used in critical applications where precise axial positioning, tensioning, or preloading is required. Whether your application involves rotating assemblies, bearing retention, or component adjustment under load, our custom parts provide the thread integrity and dimensional accuracy needed to perform reliably.

With decades of machining expertise and a focus on purpose-built solutions, we produce custom adjusting nuts in both standard and specialty formats. Every part is manufactured to meet your functional, dimensional, and material requirements—because in adjustment-critical assemblies, the smallest inaccuracies lead to big problems. Triangle ensures they never do.

CUSTOM ADJUSTMENT NUTS TAILORED TO YOUR SPECIFICATIONS

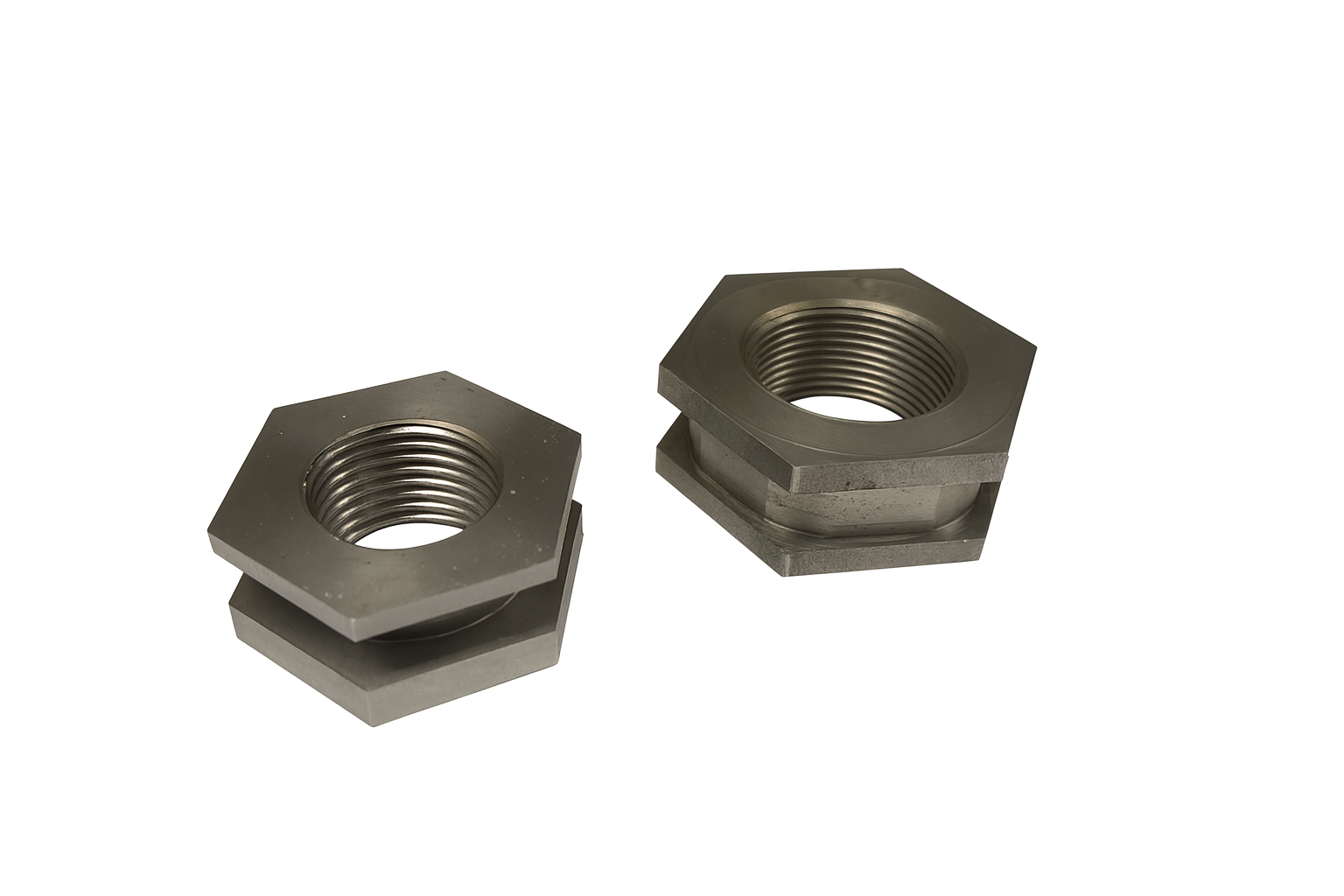

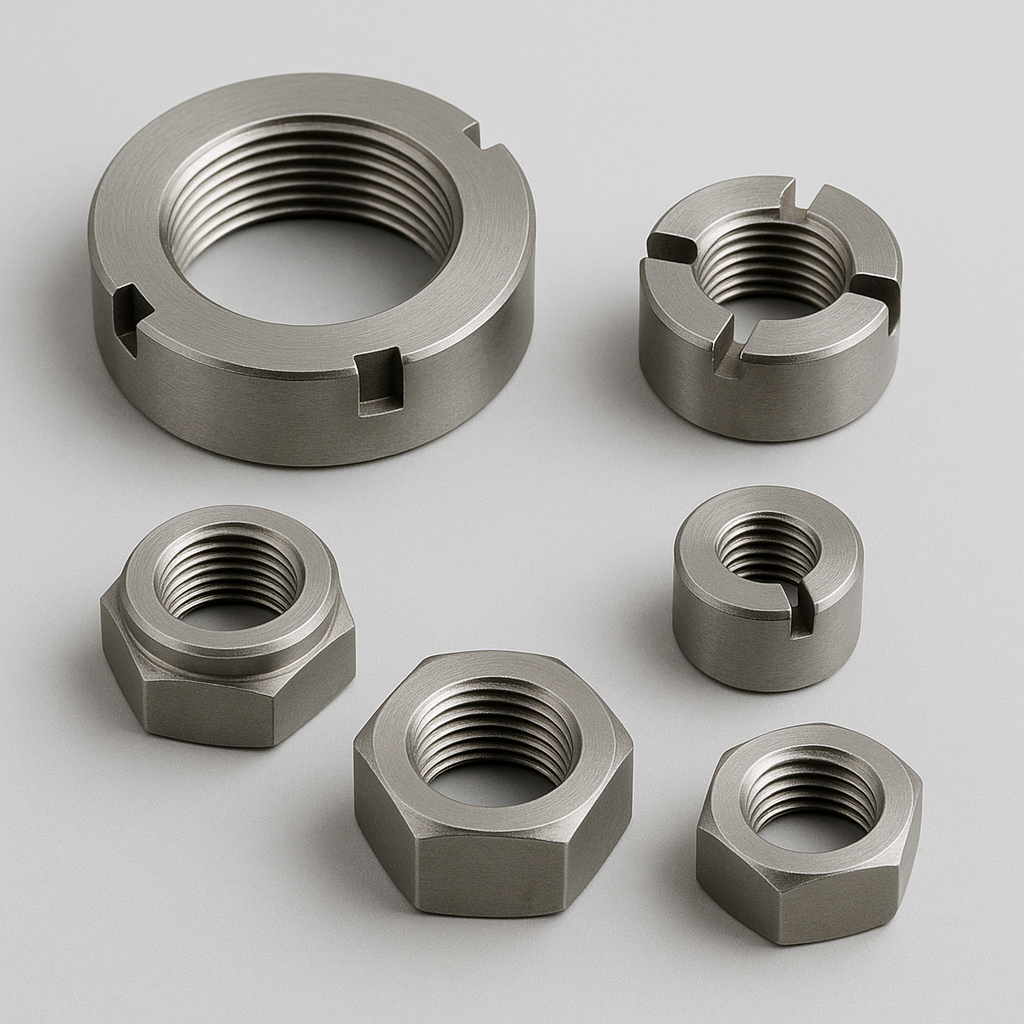

Adjusting nuts are rarely one-size-fits-all. They must match the geometry of mating components, apply the correct axial pressure, and often include features like slots, grooves, or torque points to aid in installation and fine-tuning. At Triangle Machine Products, we manufacture each adjustment nut according to your precise requirements—thread pitch, diameter, shoulder design, material, and finish are all fully customizable.

Whether you need low-profile adjusting nuts for compact assemblies, heavy-duty nuts for mechanical locking, or adjustment nuts that integrate seamlessly into fine-threaded control systems, our team machines them to spec using advanced CNC turning centers and inspection protocols. With quick changeovers and small- to high-volume flexibility, we can produce prototype quantities, limited-run adjustments, or long-term production orders without sacrificing consistency.

PRECISION ADJUSTING NUTS FOR INDUSTRIAL APPLICATIONS

Adjusting nuts serve as mechanical control points in systems where movement must be managed, locked, or fine-tuned. You’ll find them retaining bearings on shafts, adjusting end play, locking linear motion elements, or securing rotating components in dynamic assemblies. Triangle’s precision adjustment nuts are used in systems that can’t afford slippage or deformation—from hydraulic cylinders and gear housings to robotic arms and motor assemblies.

Each nut we manufacture is machined for reliable engagement, proper load distribution, and long service life. The result is a component that not only installs easily, but also maintains its position through vibration, temperature shifts, and repeated use—without relying on adhesives or secondary locking features. When your equipment is built for durability, Triangle’s components help ensure your adjustment stays locked in.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS FOR ADJUSTING NUTS?

Our customers choose Triangle because they know precision matters. When tolerances are tight and part quality can’t be left to chance, mass production methods simply fall short. At Triangle Machine Products, we bring over 70 years of machining expertise to every order, offering the process control and attention to detail required for critical-threaded components like adjustment nuts.

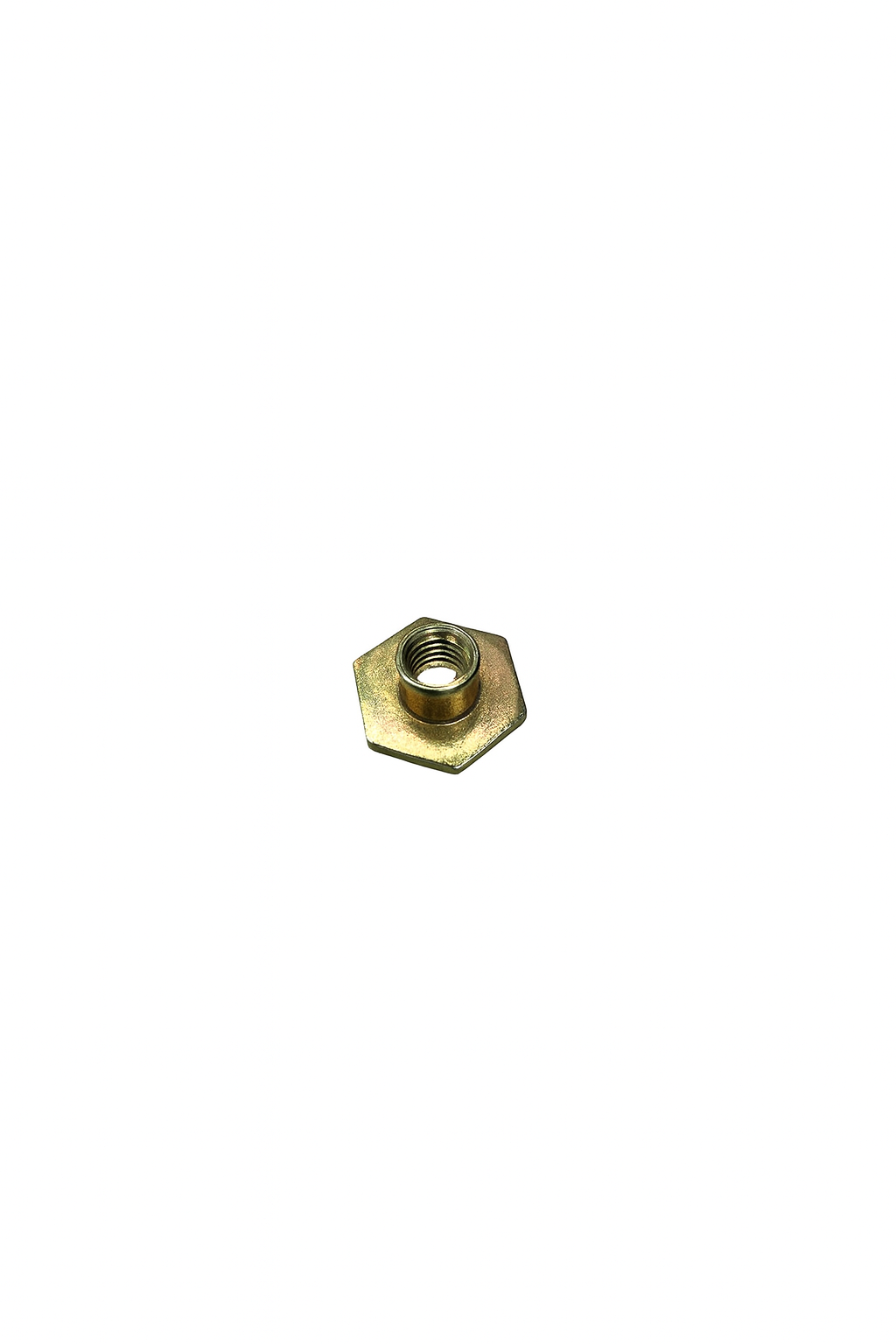

We use advanced CNC equipment and real-time inspection to hold tight tolerances across thread profiles, flange diameters, and drive features. Our experience with stainless steel, carbon steel, brass, and high-strength alloys allows us to tailor material choices to your environment—whether corrosive, high-temperature, or vibration-prone. And because we produce everything in-house, we maintain consistency from first article through final shipment.

For adjustment nuts that fit right, hold firm, and stay in spec, Triangle is the partner that delivers

ADJUSTING NUTS: FREQUENTLY ASKED QUESTIONS

WHAT ARE ADJUSTING NUTS AND HOW ARE THEY USED?

Adjusting nuts are precision-threaded components used to control axial movement, preload, or alignment in mechanical systems. They are commonly used in bearing retention, linear guides, and shaft-mounted assemblies where fine positioning or tensioning is required.

CAN TRIANGLE MACHINE PRODUCTS MANUFACTURE CUSTOM ADJUSTING NUTS?

Yes. We specialize in custom adjusting nuts machined to meet your specific design, including unique threads, flanges, reliefs, and surface treatments. Every nut is produced to exact tolerances that mass-production methods typically can’t match.

WHAT INDUSTRIES BENEFIT FROM PRECISION ADJUSTING NUTS?

Industries such as automation, robotics, fluid power, heavy machinery, and aerospace all rely on precision adjusting nuts to maintain control, reduce wear, and ensure alignment in systems where accuracy is critical to performance.

If you have any questions about our machined adjusting nuts, or the types of nuts we manufacture, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.