PRECISION SHAFT COLLARS FOR INDUSTRIAL APPLICATIONS

Triangle Machine Products manufactures precision shaft collars that deliver secure, repeatable performance in demanding industrial environments. Designed to hold components in place, align parts, or act as mechanical stops, our custom shaft collars are used in machinery, automation systems, fluid power assemblies, and rotating equipment. Every collar is machined to your exact specifications and built to withstand real-world operating conditions.

Our team serves OEMs, Tier 1 suppliers, and industrial equipment manufacturers who rely on shaft collars for both structural integrity and precise positioning. Whether your application calls for a standard clamping collar or a highly customized design with specific fit, finish, or threading, Triangle delivers durable, high-performance components built for reliability.

HIGH-QUALITY INDUSTRIAL SHAFT COLLARS FOR RELIABLE PERFORMANCE

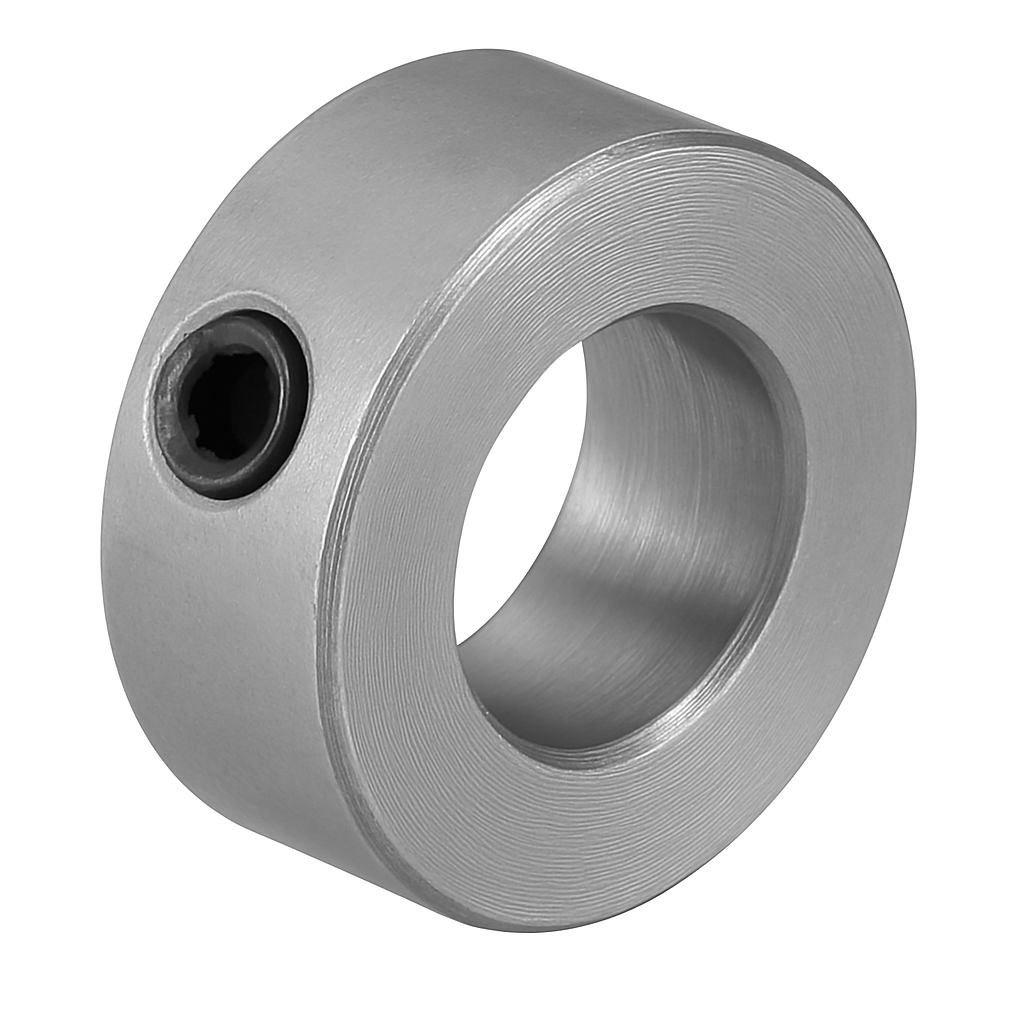

Shaft collars are simple in form but critical in function. They serve as locating devices, load-bearing components, or axial stops that hold parts securely along a shaft. At Triangle, we machine shaft collars with precision turning processes to ensure accurate bores, square faces, and smooth finishes that fit precisely and lock reliably in place.

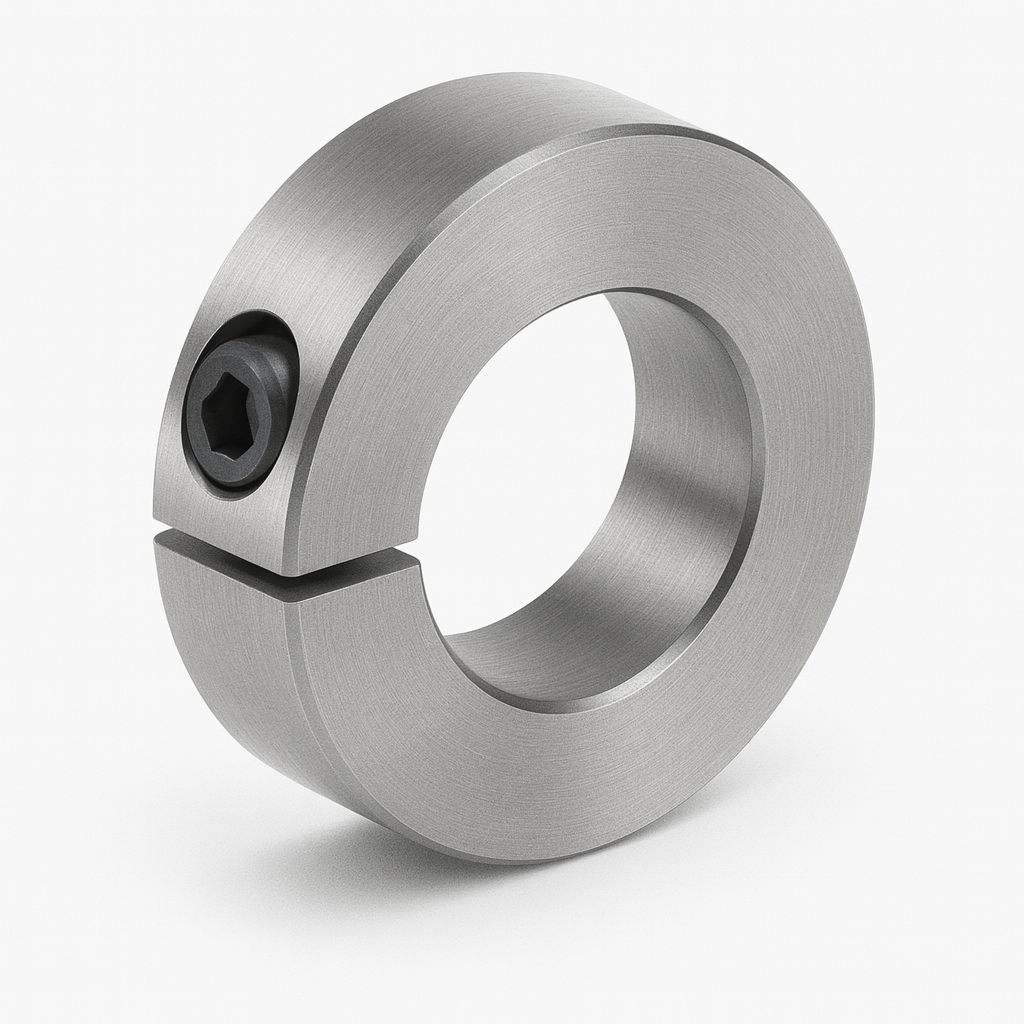

Our industrial shaft collars are used in applications ranging from linear motion systems and electric motors to hydraulic assemblies and packaging machinery. We focus on tight tolerances for inner diameter and perpendicularity to maximize holding strength and prevent misalignment or shaft damage. We also offer options for set screw, clamp-style, and threaded collars depending on your mechanical and assembly requirements.

Each shaft collar is thoroughly inspected and deburred to meet both dimensional and cosmetic standards, ensuring a clean finish and repeatable fit—whether you’re installing one or a thousand.

CUSTOM SHAFT COLLARS ENGINEERED TO YOUR SPECIFICATIONS

Every shaft collar we produce is custom-machined to meet the exact needs of your application. From one-piece and two-piece clamping designs to flanged or slotted collars, we offer full flexibility in geometry and tolerances. If your application calls for special features such as threaded bores, keyways, flats, or grooves, we can incorporate those into the machining process.

Our engineering team works with your drawings or models to ensure manufacturability and performance. We support a variety of surface finishes and coatings, including black oxide, zinc plating, and anodizing for corrosion protection or aesthetic preferences. If the collar is part of a dynamic assembly, we can also advise on material selection and tolerances to reduce wear, vibration, or galling.

With decades of experience in turned components, we understand how shaft collars interact with adjacent parts and can help you avoid issues with fit, runout, or locking force—particularly in applications where failure or slippage is not an option.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS AS YOUR SHAFT COLLAR MANUFACTURER?

Triangle Machine Products offers a unique blend of precision machining expertise, responsive engineering support, and high-mix production flexibility. We have the equipment and skill to hold tight tolerances and produce consistent, repeatable parts at both low and high volumes.

Our shaft collars are manufactured entirely in-house, which gives us complete control over quality and lead times. We use modern CNC turning equipment, backed by a robust inspection process that includes in-process checks, vision systems, and CMM verification. Each part is documented and traceable, and we offer full certifications as required.

Customers choose Triangle because we don’t just machine to print—we work as a partner to ensure your shaft collars perform in the field. Whether you’re trying to reduce assembly time, improve holding power, or solve a specific mechanical problem, we’re ready to help engineer the best possible solution.

MACHINED SHAFT COLLARS: FREQUENTLY ASKED QUESTIONS

WHAT ARE SHAFT COLLARS AND HOW ARE THEY USED IN INDUSTRIAL APPLICATIONS?

Shaft collars are mechanical components used to position, locate, or secure parts along a rotating or stationary shaft. They are commonly used as spacers, stops, or axial clamps in assemblies such as motors, gearboxes, actuators, and automation systems. Their ability to lock into place without damaging the shaft makes them a critical part of many industrial designs.

CAN TRIANGLE MACHINE PRODUCTS PROVIDE CUSTOM SHAFT COLLARS?

Yes, Triangle manufactures fully custom shaft collars in a wide range of sizes, styles, and materials. Whether you need a standard clamp collar or a highly specialized design with keyways, threads, or special coatings, we can produce it to your exact requirements with tight-tolerance machining.

WHAT MATERIALS ARE AVAILABLE FOR INDUSTRIAL SHAFT COLLARS?

We machine shaft collars from a variety of materials to suit different performance needs. Common options include carbon steel, stainless steel, aluminum, and brass. We also offer heat-treated and plated finishes to enhance corrosion resistance, wear performance, or appearance depending on your application.

If you have any questions about our machined shaft collars, our machined shaft collar turnings machines, our custom machined shaft collar creation process or anything else, including a quote, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.