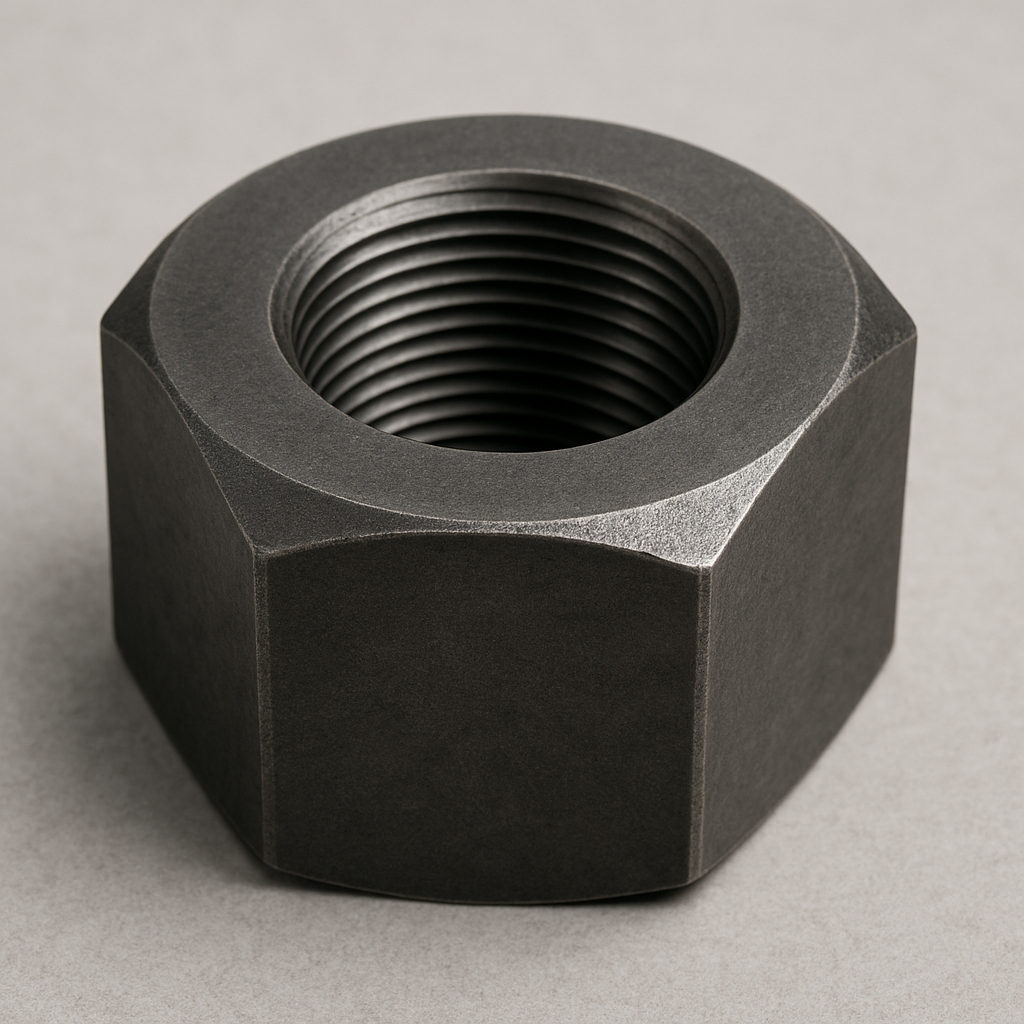

HIGH-QUALITY HYDRAULIC NUTS FOR INDUSTRIAL APPLICATIONS

Triangle Machine Products is a trusted supplier of precision hydraulic nuts for demanding industrial environments. Engineered for strength, sealing integrity, and long service life, our hydraulic nuts are machined to exact specifications to support high-pressure applications in fluid power systems. Whether you need a standard part or a specialized solution, we deliver hydraulic nuts that meet your exact fit and function.

RELIABLE HYDRAULIC NUT MANUFACTURERS AND SUPPLIER

As a leading manufacturer and supplier of hydraulic nuts, Triangle Machine Products combines modern CNC machining with decades of industry experience. We machine a wide range of sizes, thread types, and profiles with consistent repeatability, ensuring every nut meets your technical and performance requirements. Our process controls, advanced inspection methods, and robust material sourcing give you confidence in every shipment—no matter the volume or complexity.

CUSTOM HYDRAULIC NUTS ENGINEERED TO YOUR SPECIFICATIONS

Not every application fits an off-the-shelf fastener—and that’s where our custom hydraulic nut capabilities come in. Triangle Machine Products works directly with OEMs, component suppliers, and engineers to design and machine hydraulic nuts that match tight tolerances, unique thread profiles, or specialized geometries. From one-off prototypes to full production volumes, we ensure your custom hydraulic nuts are built for maximum compatibility and high-performance sealing.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS FOR HYDRAULIC NUTS?

Triangle Machine Products sets itself apart with precision, flexibility, and a deep understanding of fluid power requirements. We specialize in producing hydraulic nuts that meet demanding dimensional and surface finish requirements, supporting both sealing performance and mechanical strength. Our team is highly responsive and ready to collaborate on everything from custom configurations to long-term production partnerships. With a strong track record in supplying hydraulic fitting components, we are a trusted extension of your supply chain.

HYDRAULIC NUTS: FREQUENTLY ASKED QUESTIONS

WHAT ARE HYDRAULIC NUTS AND WHERE ARE THEY USED?

Hydraulic nuts are threaded fastening components used in high-pressure fluid systems to connect and secure components such as fittings, tubes, or valves. They are critical in maintaining a leak-free seal while withstanding high mechanical and hydraulic loads. You’ll find them across industries like mobile hydraulics, heavy machinery, construction equipment, and industrial automation.

CAN I ORDER CUSTOM HYDRAULIC NUTS FROM TRIANGLE MACHINE PRODUCTS?

Yes. We specialize in producing custom hydraulic nuts to meet your specific needs, whether it’s a proprietary thread form, a unique outside profile, or a specialty material. Our team works closely with customers to develop and manufacture nuts that integrate seamlessly into their systems and assemblies.

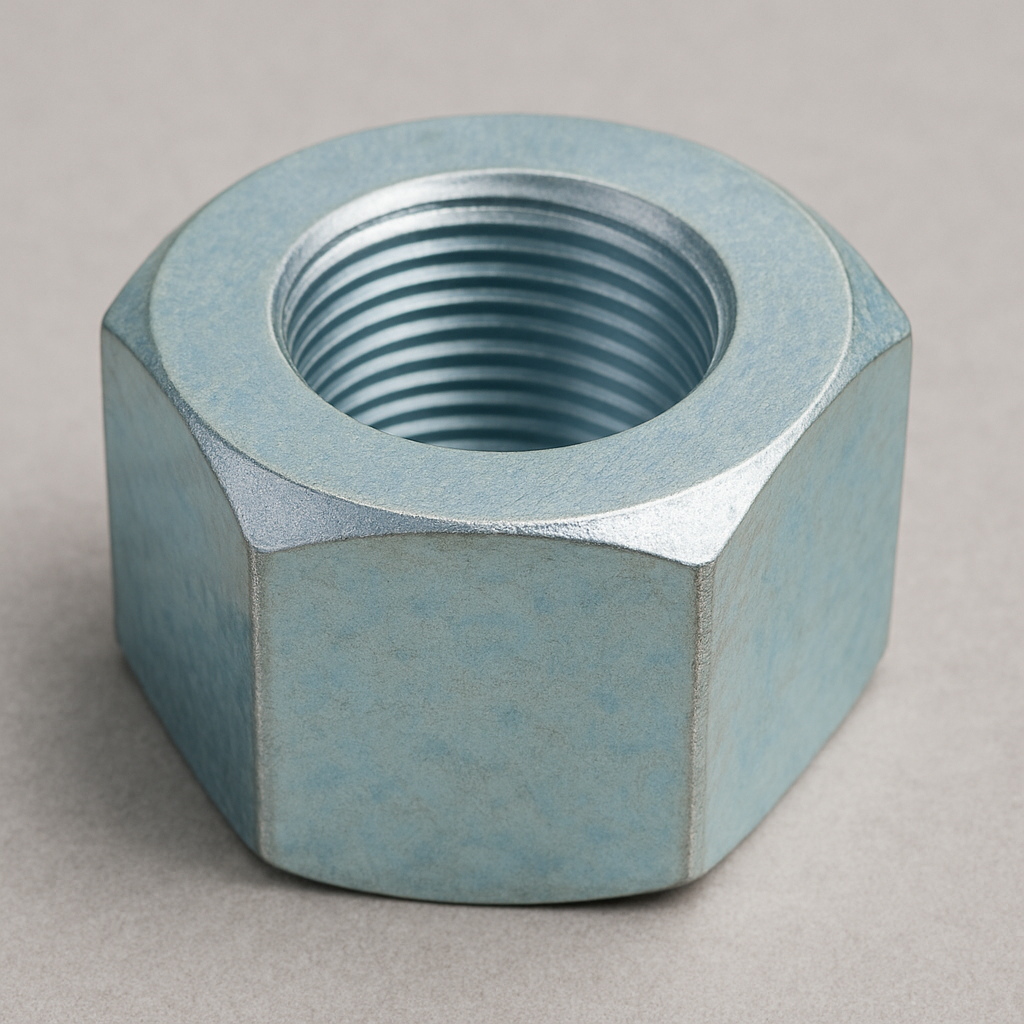

WHAT MATERIALS ARE AVAILABLE FOR HYDRAULIC NUTS?

We machine hydraulic nuts from a wide variety of materials based on your system requirements. Common options include carbon steel, stainless steel, and brass, with additional specialty alloys available for corrosion resistance or high-strength needs. All materials are sourced to meet industry specifications and can be provided with protective coatings or finishes as required.

If you have any questions about our hydraulic nuts manufacturing, or are looking for a quote, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.