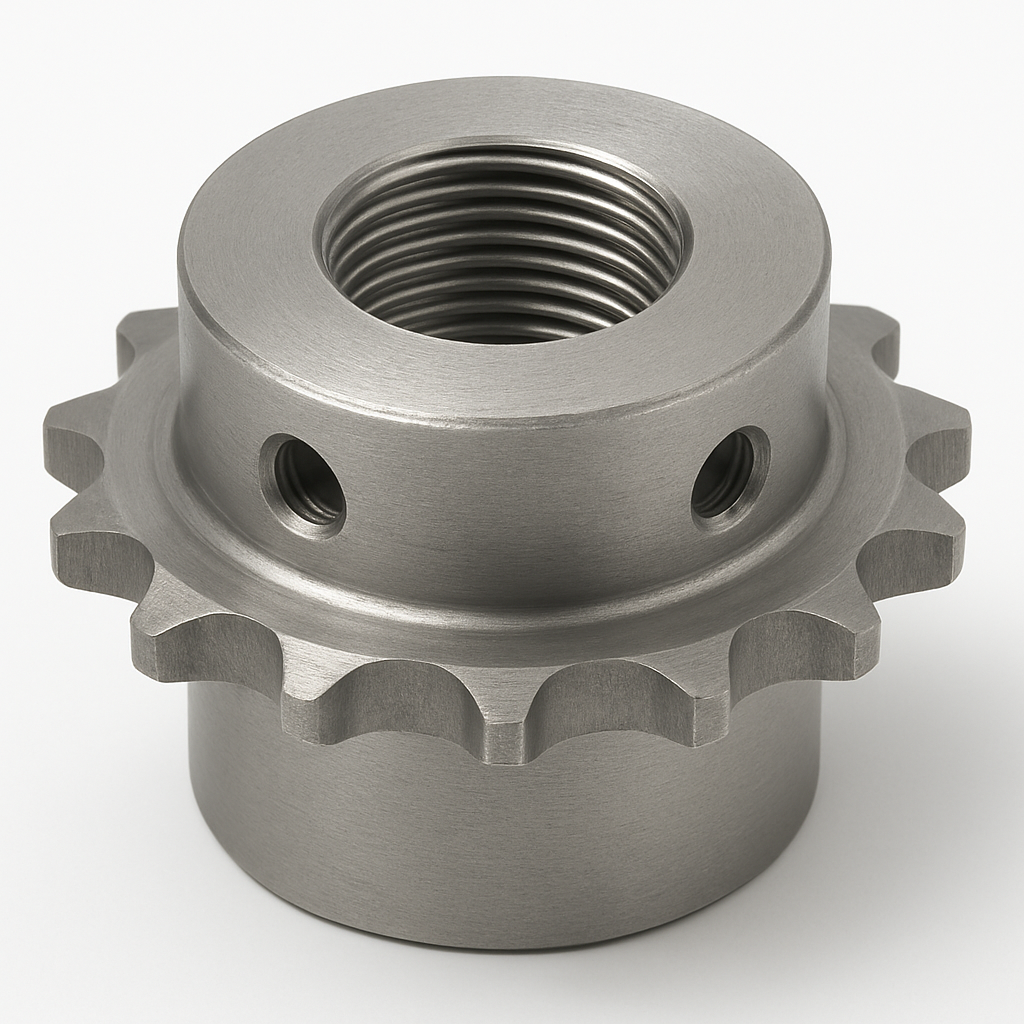

PRECISION MACHINED SPROCKET HUBS FOR INDUSTRIAL APPLICATIONS

Sprocket hubs are the driving force behind efficient chain-driven power transmission systems. Whether they’re installed in conveyor assemblies, gearboxes, or rotating mechanical linkages, their precision matters. Triangle Machine Products manufactures custom sprocket hubs that deliver dependable engagement, smooth torque transfer, and long-lasting alignment for high-demand industrial systems.

Our machined sprocket hubs are manufactured to critical tolerances and designed for repeatable performance across varying speed, load, and environmental conditions. From OEM replacement parts to new product builds, Triangle delivers your sprocket hub backed by experience, quality, and modern technology.

HIGH-QUALITY SPROCKET HUBS ENGINEERED FOR RELIABILITY

In industrial systems that depend on chain drives, the tight tolerances and consistency of your sprocket hubs directly influence uptime and operational efficiency. At Triangle Machine Products, our sprocket hubs are machined from premium-grade metals to ensure proper concentricity, precise pitch alignment, and alignment part after part.

We produce everything from simple hub blanks to fully finished parts with keyways, internal threads, and custom bore profiles. Our manufacturing team works with you, our customer, helping prevent premature wear, backlash, or misalignment that can result from lower-precision processes. When reliability matters, Triangle delivers.

CUSTOM SPROCKET HUBS AND MANUFACTURING CAPABILITIES

Every industrial drive system is unique—whether its size constraints, mounting requirements, or performance goals, your sprocket hub must fit seamlessly into the design. Triangle Machine Products offers custom sprocket hub machining tailored to your specifications, including part geometry, bore sizes, surface finish, and balancing.

We support a wide range of configurations, including split-hub, weld-on, and keyless locking designs, and can machine from bar stock, blanks, or customer-supplied forgings. Our CNC machining centers and integrated CAD/CAM systems allow us to produce complex features consistently and repeatedly—whether you’re ordering 25 parts, 25,000,000 or more.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS AS YOUR SPROCKET HUB MANUFACTURER?

When you’re sourcing machined sprocket hubs, choosing the right manufacturing partner is critical. Triangle Machine Products is built for high-precision production, with decades of machining experience, specialized equipment, and a process-first mindset. Unlike mass-production methods like casting or forming, our CNC machining ensures superior dimensional accuracy and surface integrity—qualities essential for performance and longevity in chain-driven applications.

With responsive service, engineering collaboration, and quality control built into every run, Triangle delivers sprocket hubs that outperform off-the-shelf alternatives.

SPROCKET HUBS: FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF SPROCKET HUBS DO YOU MANUFACTURE?

We manufacture a variety of sprocket hubs including weld-on hubs, taper-lock hubs, finished bore hubs, and custom hybrid configurations. Each is machined to tight tolerances for maximum performance.

CAN YOU PRODUCE CUSTOM SPROCKET HUBS FOR UNIQUE APPLICATIONS?

Yes. Whether you need a custom bore, offset spacing, specific hub dimensions, or enhanced wear resistance, Triangle can manufacture to your drawing or help design a part that meets your requirements.

WHAT MATERIALS ARE AVAILABLE FOR INDUSTRIAL SPROCKET HUBS?

We commonly machine sprocket hubs from carbon steel, alloy steel, stainless steel, and other specialty materials depending on the environment and mechanical requirements. Surface treatments like black oxide, zinc plating, and nitriding are also available.

If you have any questions about our custom sprocket hubs, our specialty sprocket hubs, or the types of sprocket hubs we manufacture, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.