PRECISION SPLINED HUBS FOR INDUSTRIAL APPLICATIONS

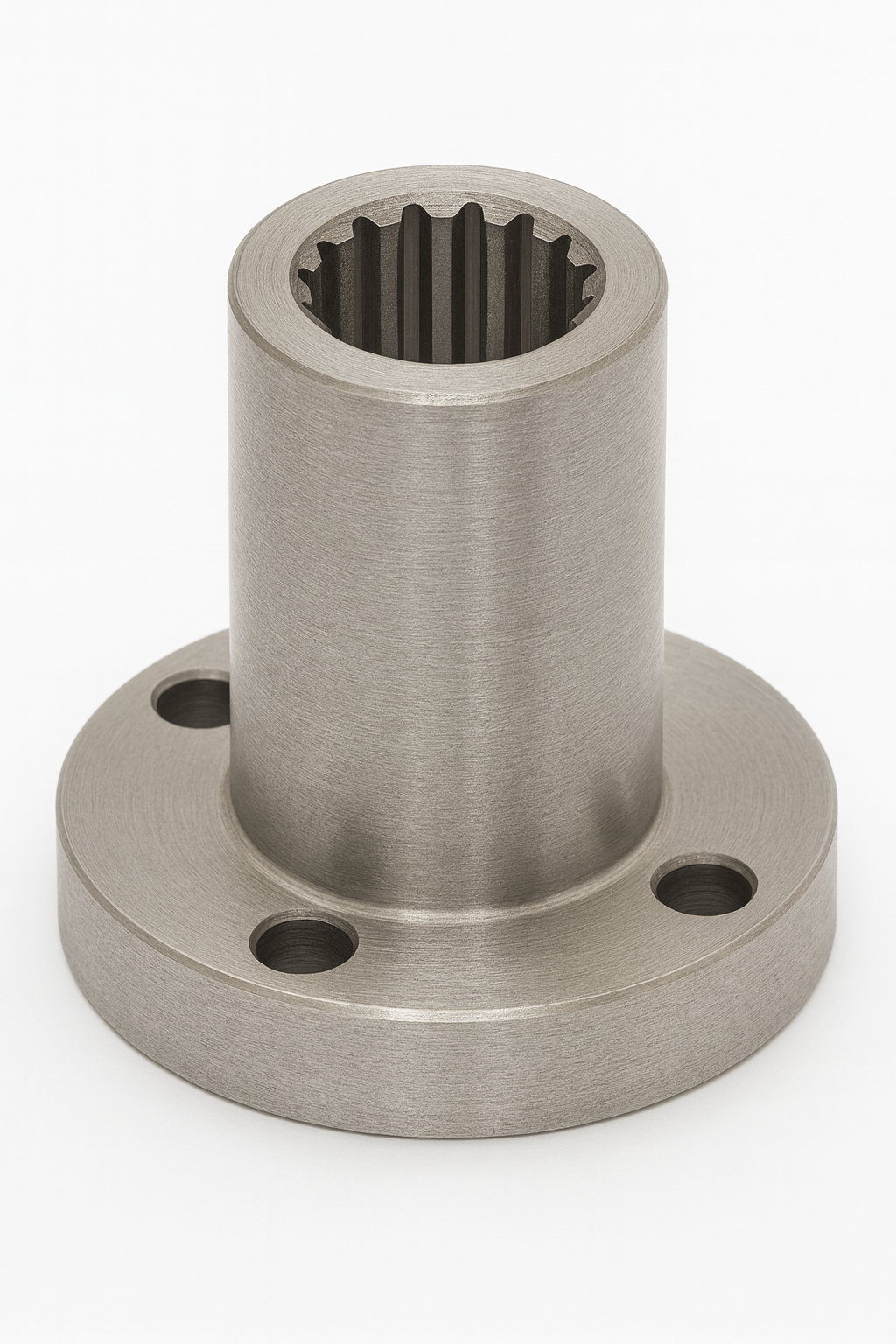

When torque must be transferred with precise alignment and minimal backlash, spline hubs are the interface of choice. Triangle Machine Products manufactures precision-machined spline hubs for mechanical systems requiring exact shaft engagement and rotational synchronization. These components are essential in applications where timing, strength, and shaft-to-hub stability cannot be compromised.

Rather than relying on standard fitments or off-the-shelf solutions, we offer custom spline hub machining to suit the specific geometry, load conditions, and performance requirements of your system. Whether your needs involve internal or external splines, involute forms, or custom broach profiles, Triangle provides reliable solutions engineered to last.

HIGH-QUALITY SPLINE HUBS ENGINEERED FOR PERFORMANCE

Spline hubs serve as critical coupling points between rotating shafts and drive components in mechanical assemblies. At Triangle Machine Products, we engineer industrial spline hubs that are tightly toleranced and built for sustained operation in high-torque, high-duty-cycle environments. These hubs are often integrated into gear assemblies, couplings, or rotational drives where precision alignment and load distribution are vital.

Each spline hub is machined to your exact specifications—that include tight runout control, concentricity, and matched spline profiles. Whether the application involves timing-sensitive machinery or power delivery systems in automotive, aerospace, or heavy equipment industries, our hubs are built to maintain exact engagement and reduce wear on mating components.

CUSTOM & PRECISION SPLINED HUBS TO MEET YOUR SPECIFICATIONS

Every spline interface is different, and precision matters at every engagement point. Triangle Machine Products specializes in custom spline hub manufacturing, offering full control over geometry, tolerance, and finish to meet your application’s exact requirements. Whether you’re working with ANSI, SAE, DIN, or custom spline forms, we machine internal or external hubs from a range of materials to ensure durability and fit.

From low-volume prototypes to long production runs, our advanced CNC turning and milling capabilities ensure that each spline hub is machined to spec. We routinely support shaft-hub assemblies, keyed and splined connections, and complex broached designs that other manufacturing processes—like cold forming or casting—simply cannot achieve with the same level of accuracy.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS FOR INDUSTRIAL SPLINED HUBS?

As a trusted manufacturing partner, Triangle Machine Products delivers more than just machined parts—we deliver performance you can build on. Our experience in precision spline hub machining is backed by advanced inspection processes, CAD/CAM programming, and a commitment to tight-tolerance manufacturing.

Unlike generic component suppliers or high-volume cold formers, we provide tailored machining solutions that ensure optimal alignment, torque handling, and part longevity. Customers across automotive, automation, agricultural, and industrial sectors rely on our spline hubs to deliver stable mechanical connections in mission-critical systems. When tolerances, timing, and torque transmission matter, Triangle is the machining partner that delivers.

SPLINED HUBS: FREQUENTLY ASKED QUESTIONS

WHAT ARE SPLINED HUBS AND WHAT ARE THEY USED FOR?

Spline hubs are components with ridged or grooved profiles that interlock with mating shafts to transmit torque. They’re used in gearboxes, couplings, and drive systems across automotive, aerospace, and heavy industrial machinery.

CAN TRIANGLE MACHINE PRODUCTS MANUFACTURE CUSTOM AND PRECISION SPLINED HUBS?

Yes. We manufacture custom spline hubs based on your required form, fit, and performance—including involute splines, straight-sided profiles, and broached internal splines.

WHAT MATERIALS ARE AVAILABLE FOR INDUSTRIAL SPLINED HUBS?

Common materials include carbon steel, alloy steel, stainless steel, and high-strength aluminum. Material selection is based on your required load-bearing, environmental, and performance needs.

If you have any questions about our custom splined hubs, our specialty splined hubs, or the types of spline hubs we manufacture, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.