PRECISION MACHINED PULLEY HUBS FOR INDUSTRIAL APPLICATIONS

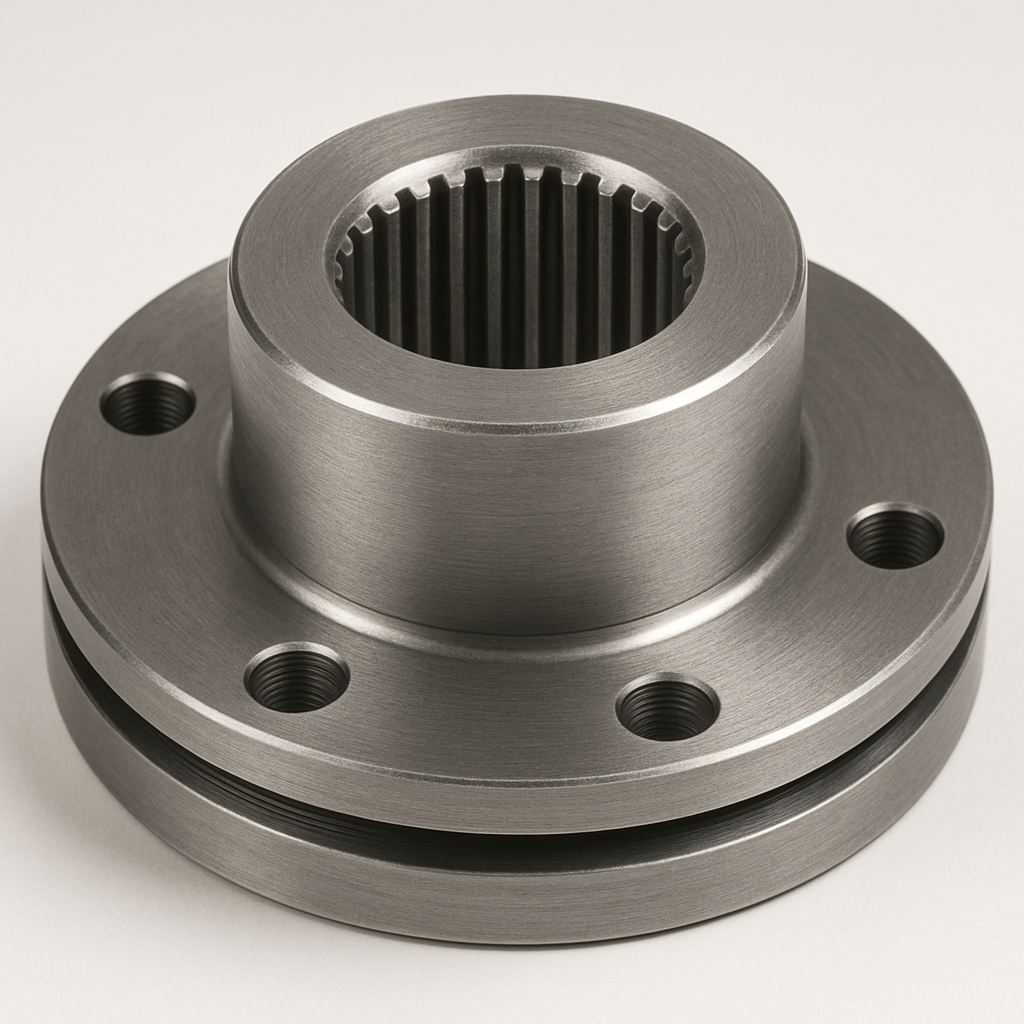

Pulley hubs serve a vital role in power transmission, acting as the interface between drive shafts and belts in rotating equipment. At Triangle Machine Products, we manufacture precision machined pulley hubs that ensure optimal belt alignment, torque transfer, and long-term reliability for a wide range of industrial systems. Whether used in a V-belt, round belt, or Poly-V drive configuration, our pulley hubs are built to deliver consistent performance under demanding conditions.

Designed with concentricity, runout control, and secure shaft fitment in mind, our machined pulley hubs help reduce vibration, extend belt life, and improve operational efficiency. Triangle’s in-house machining capabilities allow us to meet tight tolerances that casting or cold-formed processes simply can’t match.

HIGH-QUALITY PULLEY HUBS ENGINEERED FOR PERFORMANCE

Every rotating system depends on the integrity of its mechanical interfaces—and the pulley hub is no exception. Triangle Machine Products engineers industrial pulley hubs to maintain precise alignment and balanced rotation across a variety of drive systems. From electric motor assemblies to heavy-duty conveyors and automated machinery, our hubs are built to integrate seamlessly into your design.

We machine pulley hubs with features such as straight and tapered bores, keyways, pilot diameters, and custom bolt hole patterns. Our team also accommodates specific drive configurations, including Poly-V grooves, flat belt interfaces, and V-belt mating geometries. With full control over dimensions, finishes, cleanliness, and special packaging, Triangle provides pulley hubs that perform over time.

CUSTOM PULLEY HUBS TO MEET YOUR SPECIFICATIONS

Off-the-shelf hubs often fail to meet the unique dimensional and performance requirements of custom machinery. Triangle Machine Products fills that gap by offering custom pulley hub machining based on your specifications. Whether your assembly demands a nonstandard shaft diameter, special mounting flange, or weight-reduction geometry, we deliver a machined solution that fits the application without compromise.

We routinely work with carbon steel, stainless steel, and aluminum alloys, and can accommodate special surface finishes or coatings as needed. Whether you’re designing a new drive system or replacing a legacy hub, Triangle’s experience in precision machining and design-for-manufacturability helps you move from concept to production with confidence.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS FOR YOUR INDUSTRIAL PULLEY HUBS?

When choosing a supplier for machined pulley hubs, accuracy and consistency are key. Triangle Machine Products delivers both—leveraging decades of machining experience and state-of-the-art CNC equipment to produce hubs that meet your exact design intent. From single prototypes to long production runs, our process ensures dimensional integrity, repeatability, and performance across every order.

Unlike formed or cast options, our machined pulley hubs hold tighter tolerances, which helps prevent misalignment, belt tracking issues, or premature component wear. Customers across a range of industries—from material handling and packaging to industrial automation and HVAC—rely on Triangle for hubs that support smoother, quieter, and more efficient operation.

PULLEY HUBS: FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF PULLEY HUBS DO YOU MANUFACTURE?

We manufacture a range of pulley hubs including hubs for V-belt drives, Poly-V systems, and round belt configurations. Each hub is precision-machined to your specific geometry, including keyways, bore types, and mounting surfaces.

CAN I ORDER CUSTOM PULLEY HUBS FOR MY SPECIFIC NEEDS?

Yes. Triangle Machine Products specializes in custom pulley hub machining to match your performance, dimensional, and material requirements. We can machine to print or collaborate with your team to refine the final design.

WHAT MATERIALS ARE AVAILABLE FOR INDUSTRIAL PULLEY HUBS?

We commonly machine pulley hubs from carbon steel, stainless steel, and aluminum alloys. If your application requires corrosion resistance, weight savings, or enhanced strength, we can recommend the most suitable material.

If you have any questions about our custom pulley hubs, our specialty pulley hubs, or the types of pulley hubs we manufacture, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.