PRECISION MACHINED IMPELLER HUBS FOR INDUSTRIAL APPLICATIONS

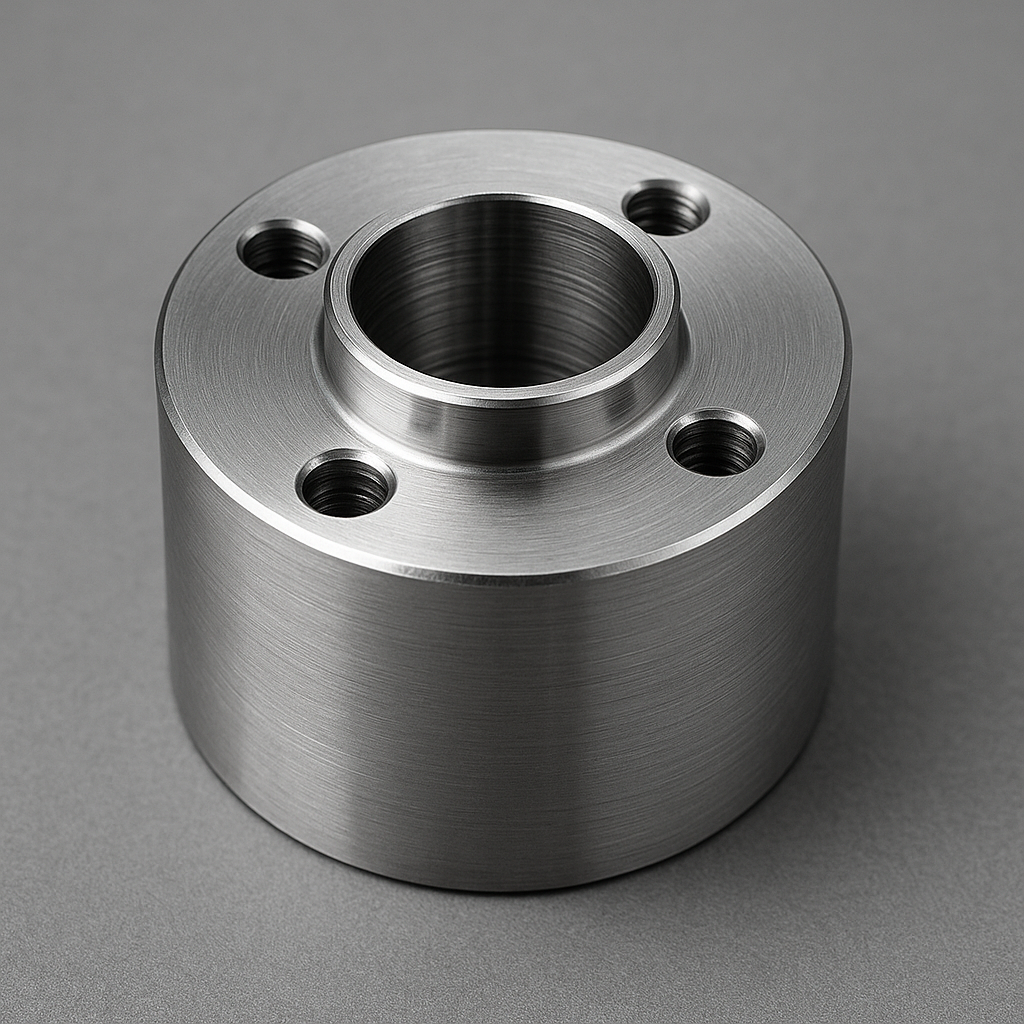

At the center of every high-performing impeller assembly is a hub that needs to withstand rotational stress, vibration, and complex mounting conditions. Triangle Machine Products manufactures precision machined impeller hubs that meet the demands of industrial fluid movement and power transmission systems. Our impeller hubs are engineered to maintain balance, support dynamic loading, and ensure stable rotation over time—making them a dependable core for impellers used in pumps, compressors, fans, blowers, and other rotating equipment.

Whether your project calls for small-diameter hubs with tight axial tolerances or larger hubs with intricate mating geometry, Triangle delivers fully machined impeller hubs that perform with precision under real-world conditions.

HIGH-QUALITY INDUSTRIAL IMPELLER HUBS FOR RELIABLE PERFORMANCE

In high-speed or pressure-driven applications, impeller hubs carry the mechanical load of the blades and transmit torque from the drive shaft to the working fluid. Triangle’s industrial impeller hubs are manufactured with these operating conditions in mind. We machine each hub to your exact specifications, ensuring that shaft fits, bolt patterns, and balancing features align perfectly with the rest of the assembly.

Our team produces impeller hubs with a wide range of features—including stepped bores, keyed or splined inner profiles, bolt circles, and weight-reduction pockets. Machining these hubs from solid bar stock allows us to deliver superior dimensional accuracy and surface finishes compared to cast or molded alternatives. The result is a hub that fits right the first time—and runs reliably every cycle thereafter.

CUSTOM MACHINED IMPELLER HUBS TO MEET YOUR SPECIFICATIONS

No two impeller systems are exactly alike. That’s why Triangle Machine Products offers custom impeller hub machining built around your application. Whether you require a specialized bore tolerance, concentricity control, custom flange configuration, or a high-performance material, our team works closely with your engineers to deliver a hub that integrates seamlessly into your system.

We use advanced CAD/CAM programming and multi-axis CNC machining to achieve complex geometries with tight tolerances, even in smaller production runs. From OEM replacement parts to new system prototypes, Triangle offers the flexibility to deliver impeller hubs that meet your dimensional, mechanical, and material specifications—without compromise.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS FOR YOUR MACHINED IMPELLER HUBS?

What sets Triangle apart among impeller manufacturing companies is our commitment to consistency, accuracy, and responsiveness. We don’t cast or forge parts to net shape—we machine them with precision from the ground up, ensuring each feature, fit, and surface is held to exacting standards. This is especially critical for impeller hubs, where even small deviations in symmetry or balance can lead to vibration, inefficiency, or premature failure.

Triangle supports both prototype and production orders and is built to respond to changes quickly—whether you’re iterating a design or scaling up. Our in-house machining, inspection, and setup optimization give us control over cost and lead time, while our long-standing focus on industrial applications ensures that the parts we deliver are built to last in challenging environments.

IMPELLER HUBS: FREQUENTLY ASKED QUESTIONS

WHAT ARE IMPELLER HUBS AND WHERE ARE THEY USED?

Impeller hubs are central components in rotating impellers used in pumps, compressors, fans, blowers, and other fluid-handling equipment. They provide the structural interface between the shaft and the blades, transmitting torque while maintaining alignment and rotational balance.

DOES TRIANGLE MACHINE PRODUCTS OFFER CUSTOM MACHINED IMPELLER HUBS?

Yes. Triangle machines custom impeller hubs to your specifications—including features such as tapered or stepped bores, keyways, bolt hole patterns, or splines—produced from solid bar or forging to meet your application’s exact needs.

WHAT MATERIALS ARE AVAILABLE FOR INDUSTRIAL IMPELLER HUBS?

We commonly machine impeller hubs from carbon steel, stainless steel, aluminum, and specialty alloys depending on your performance, corrosion resistance, and environmental requirements.

If you have any questions about our custom impeller hubs, our specialty impeller hubs, or the types of impeller hubs we manufacture, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.