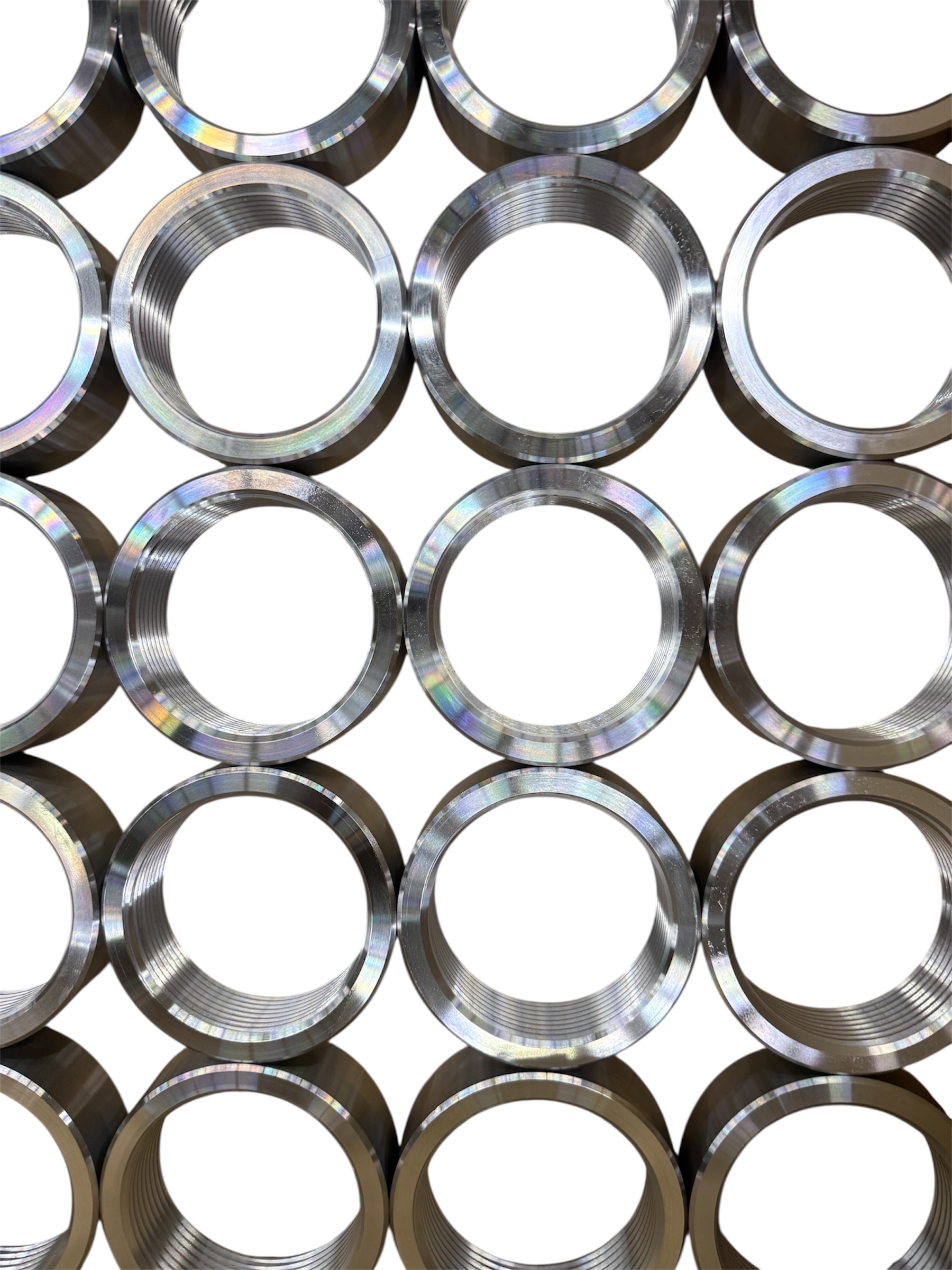

THREADED BUSHINGS MANUFACTURER: STANDARD & CUSTOM SOLUTIONS

Triangle Machine Products is a trusted manufacturer of threaded bushings, offering both standard and fully custom solutions for industries that require precision fit, durable threads, and dimensional consistency. Whether you’re reinforcing threads in softer materials, adapting thread sizes, or creating a reliable interface between components, our bushings are engineered and machined for performance and long-term reliability.

Our parts are fully machined—not cast or formed—ensuring superior control over thread engagement, concentricity, and surface quality. From custom threaded bushings to high-volume production of critical components, Triangle delivers dependable results for even the most demanding applications.

HIGH-QUALITY THREADED BUSHINGS FOR EVERY APPLICATION

Threaded bushings serve a wide range of functions in mechanical assemblies, acting as inserts, reducers, adapters, or wear-resistant fastening points. Whether they’re installed in housings, panels, rotating assemblies, or structural components, these bushings must hold up to repeated threading, vibration, and torque loads without degrading or backing out.

Triangle’s threaded bushings are machined to tight tolerances to ensure exact thread profiles, accurate bore sizes, and secure fitment. We support a variety of thread types—UN, metric, NPT, BSPP—as well as custom diameters and lengths. In many cases, our customers require bushing components that serve not only as a mechanical interface but as a precision alignment or load-bearing surface. That’s where our expertise in close-tolerance turning and threading provides a clear performance edge over generic, mass-produced inserts.

CUSTOM THREADED BUSHINGS TO MEET YOUR SPECIFICATIONS

Every application comes with unique challenges—and Triangle Machine Products meets them with tailored solutions. We manufacture custom threaded bushings to meet your specific dimensional and functional requirements, including features such as hex drive heads, flange shoulders, stepped diameters, counterbores, and internal or external threads.

Our CNC turning and milling equipment allows for rapid setup and flexible production, whether you need a single prototype or thousands of production components. Materials are selected to match your application’s strength, wear, and corrosion resistance needs—carbon steel, stainless steel, brass, and aluminum are commonly used, with additional alloys available upon request. From aerospace assemblies to automated tooling fixtures, Triangle machines each bushing to integrate precisely into your build.

WHY CHOOSE TRIANGLE MACHINE PRODUCTS AS YOUR THREADED BUSHING MANUFACTURER?

As a leading threaded bushing manufacturer, Triangle Machine Products provides more than just precision machining—we deliver reliable performance. Many commercially available bushings are formed, sintered, or molded, which can result in inconsistent threads, poor surface finishes, or dimensional variability. Our approach is different: we machine each part to exact specifications, controlling tolerances, finish, and fit from start to finish.

We work closely with engineers and buyers to understand the end use, design around real-world performance, and deliver parts that perform in the field—not just on paper. Whether your threaded bushings are locking inserts, alignment guides, or pressure-retaining adapters, Triangle ensures each component meets your standards and functions with confidence.

THREADED BUSHINGS: FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF THREADED BUSHINGS DO YOU OFFER?

We manufacture a wide range of threaded bushings, including internally and externally threaded bushings, hex drive bushings, flanged bushings, reducer bushings, and specialty adapters—all machined to precise thread profiles and dimensional tolerances.

CAN I REQUEST CUSTOM THREADED BUSHINGS FOR MY SPECIFIC REQUIREMENT?

Yes. Triangle Machine Products specializes in custom threaded bushings made to your exact specifications, including thread type, bore size, drive features, and material selection for demanding or non-standard applications.

WHAT INDUSTRIES DO YOU SERVE AS A THREADED BUSHINGS MANUFACTURER?

We supply threaded bushings to industries such as automation, fluid power, aerospace, heavy equipment, transportation, defense, and general industrial manufacturing—anywhere precise, high-strength threaded interfaces are required.

If you have any questions about our machined threaded bushings, or our custom machined threaded bushing creation process or anything else, including a quote, feel free to contact us! You can speak to the sales team at our Cleveland office directly by calling 216-524-5872, or you can fill out an online contact form. You can also check out our FAQ page for more answers to commonly asked questions. We’re excited to hear from you.